![]()

![]() Norfolk & Western Y6a Project Update

Norfolk & Western Y6a Project Update

All information and images protected, Copyright © 1997- 2023 Kohs & Company Inc, All Rights Reserved |

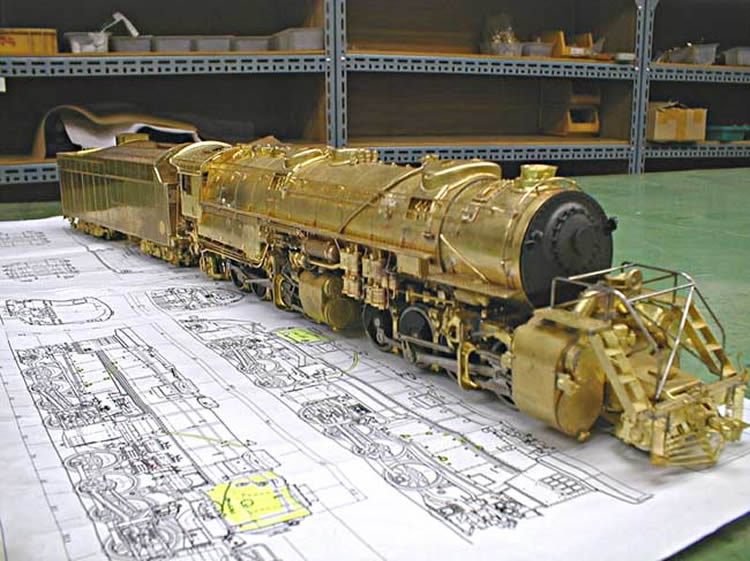

Availability: This project sold out long ago, if you are interested in acquiring one of my N&W Y6a models, please make me aware of your desire using my contact information and I will do my best to accommodate your request. Also, be sure to check out the Roundhouse page for a listing of available Kohs & Company produced models. Original Price: $4,250.00USD Versions Produced: 4 Production Quantity: 50

9/27/07 - Back on the 12th of July we had two of our Y6a's available for sale and both sold immediately. 7/12/07 - We want to advise that we have a Y6a model available for sale, if this is of interest to you, please contact us directly for the details. 11/22/03 - Finally, our Y6a's have been cleared through customs and it only took a week this time! We anticipate that the shipping will go very quickly since the production looked so good, there will be little to tweak during the pre-delivery inspection. We sincerely thank all of you with reservations that have been so patient in waiting for the final delivery, we believe that you will feel the wait was worth it when you see the finished product. We will be doing one last in-print project update just to wrap up some of the historical detail that went into producing our Y6a, this will happen once we have caught up with the delivery and it will be mailed to all that purchased a model. 11/11/03 - Just a brief update regarding the delivery of the Y6a models; as of this date, the models are in Detroit and the customs clearance process is being finalized..........finally!! We will update again as soon as the models are going out the door to customers with reservations, that should begin to happen before the end of this week. 11/03/03 - The next batch of photos will be posted to the site shortly, these will include shots of the unlagged version of the model along with the roller-bearing journal tender. We are also awaiting an update regarding the delivery of the models from Korea which should be happening very shortly, once we have the info it will posted to this location. 10/24/03 - The first two dozen photos of our production sample model have now been posted to the project site, they were taken of a version four road number 2170 model with lagged smokebox. Additional photos will be posted showing the various unique details from our other three versions of this project. 10/20/03 - We are now starting to post the photos of the Y6a production sample model, there will be a number of new images added as quickly as we can process them. Check back over the next couple of days for the latest! 10/05/03 - Another inspection trip is complete and the Y6a production models look fantastic! We could not be more pleased with the results of the effort that went into this project, it is our finest project to date. We'll be posting photos of the production models to the site as soon as possible, including some comparing the Y6a to the Y6b. We are still amazed how different the two models look sharing as many components as they do. Our 22C tender has to be seen in person to fully appreciate the fidelity of the detail that Sun Jin Models has captured with their efforts on this project, our sincerest appreciation goes out to the staff that is responsible for bringing our vision of the Y6a prototype to life in miniature. Air shipment arrangements are being made now to bring the finished models to our door step and as soon as they are finalized we will make that information available to our reservation holders that are anticipating the delivery of their new models. 9/27/03 - The production is complete and final inspection will be underway shortly!! This is the quickest project that we have developed to date, due in large part to the fact that the Y6a shares many design attributes with the Y6b which was our previous project. We are thrilled with the results and this project again breaks new ground in replicating the prototypes detail. Our early sample model was shown at the recent Indy O Scale Meet and received rave comments from all that viewed it, although most found it difficult to understand, it was explained that over 160 improvements were made to the final production models based on what was viewed at the show. It should be noted by those holding reservations that final notices will be going out early this coming week so we will be prepared to start shipping as soon as the models arrive in country. A final printed project update will be prepared using models from our production and it will mailed to all expressing an interest. 8/23/03 - Just a brief update for our reservation holders on this project; the order confirmation forms are in the mail at this point and you should be receiving them shortly, many thanks for your patience. Due to the fact that this project is moving so quickly and will be completed next month, we will not be requesting an incremental payment as planned, the balance due will be payable upon completion of the project and when the models are ready for delivery. Additional information and production photos will be available shortly. 8/05/03 - With the recent trip to Korea complete, we are now working on sending out the order confirmations for the Y6a project. In brief, this project is progressing smoothly and will be completed by the end of September this year and will mark the quickest project we have done to date. The rapid progress is obviously related to the fact that much of the Y6a project is based on our Y6b previously completed, but in viewing the models side by side they appear very different. Shown below is a sample of the tender layering which was previously described, in this sample the rivet pattern has been punched. For those not familiar with 'punched' rivets, they are in fact punched into the metal using specially developed tooling that creates a physical depression in the back side of the brass sheet, which on the face side raises a perfectly sized rivet head shape. Creating rivets by using the photo-etch process is usually one of the first compromises that importers make in developing specifications for model projects because it is much less expensive and likewise faster, most all of our competitors routinely use the photo-etch approach. There are two very distinctive differences in the results of the two approaches; first, punching rivets creates a round head with no square edges unlike photo-etching and secondly, the photo-etching of rivets leaves a perfectly flat sheet with no 'waves' that are so characteristic of tender tank sheeting. The prototypically characteristic waves are induced by the mechanical process of punching rivets which is actually stretching the metal sheeting in a predetermined pattern.

7/27/03 - A brief update for those of you that have sent in reservations for our Y6a; reservation confirmations will be going out shortly, we are just processing the last of the orders that have come in and the confirmations will follow. We will also be posting photos of the production in process very soon, these will show many of the over 120 changes that have been made since showing the original sample model. At this point we are as excited about the tender as we are the locomotive, with many models the tender receives short attention, but for us it is every bit as important as the locomotive. 6/17/03 - The image below shows how the Y6a tender tank sheeting is being machined to correctly model the three (3) prototypical sheeting layers of the 22-C tender. Once the sheeting is machined, the rivet detail will be hand punched to replicate both the size and shape of the rivets. Many other builders simply replicate rivet detail by using the photo-etching process which is much quicker, easier and cheaper to do, but it does not yield a correctly shaped rivet head. Hand punching rivets requires special tooling and unique patterns for individual projects as a result it is much more expensive and time consuming to accomplish. Previously, overlap detail on other models has been signified by simply scribing or etching a line in the sheeting to locate a seem, we believe that ours is the first effort to correctly model the actual seems.

6/15/03 - The mailing of reservation packets has begun to our existing clients and many should already have them in hand. All existing clients will automatically receive the information and have a chance to reserve a model before we open the project up to general reservations. The balance of the mailing to clients will be complete in the next two days and by the first of next week we will begin mailing to all that have expressed an interest, but are not yet clients. The process will go quickly with only fifty (50) units to sell. 6/04/03 - The offering packages for this project have started to flow to our existing customers, as usual, our customers receive the first opportunity to reserve new projects. Shortly after our existing customers have had their opportunity we will send out the reservation material to anyone else that has expressed an interest or specifically requested a reservation. There will be only 50 units and they will go fast, if you hesitate you will probably miss out on our finest effort thus far. The final corrections are complete and this project is in production. We made well over 100 changes to the sample model, photos of which have been posted on the project site, the Y6a promises to be even better than our much acclaimed Y6b. We expect the completion of production in September of this year. The offering materials will be available for download from this site once all of those that have requested reservations receive their materials. 4/19/03 - The first sample is nearly complete at this point and the final corrections will follow as soon as it is complete. The images below are the first of many to come, most will be posted once the sample has arrived in our shop for a thorough examination. So far, all is progressing smoothly and we're very excited about the results and the quality of the work, this will be the best first sample to date. Stay tuned for upcoming images in the near future.

Above - Sheet metal parts for the cab and firebox prior to being formed.

Above - Cast parts for the plain-bearing trucks on the tender.

Above - 22-C tender components ready for test assembly.

Above - Another view of the 22-C tender showing the tender underbody with it's correct corrugation pattern.

Above - The first sample nearing completion, but not quite complete with all of it's detail. 3/01/03 - The design of this project is complete, all that remains is to finalize the version detailing and we are hard at work wrapping up the necessary research. |